Green Launch Project Updates

July 2022

SUB ORBITAL ACTIVITY

Green Launch has multiple contracts with customers that are interested in the unique services of Green Launch (GL) for sub-orbital delivery and atmospheric sampling.

Delivering sub-orbital payloads and atmospheric sampling are becoming a strong focus and we will perform a launch series at Yuma Proving Ground in Arizona during the Fall of 2022.

These low-cost launches should lay the foundation for the future Green Express launcher which will deliver satellites and supplies to Low Earth Orbit.

January 2022

FIRST VERTICAL LIGHT-GAS LAUNCH FOR SPACE ACCESS BY GREEN LAUNCH

January 13, 2022 XX:XX Eastern Daylight Time

Escondido, Calif.—(BUSINESS WIRE) Eric Robinson, Co-Founder of Green Launch has announced the first vertical Light-Gas launch for space access.

GREEN LAUNCH, in a quantum leap for space access and exploration, on their first vertical attempt, launched a projectile into the stratosphere. The launch propellant featured hot hydrogen which is the fastest gas known. The 54 foot long launch tube accelerated the payload to a velocity exceeding Mach 3. This “proof of concept” impulse launch, paves the way for higher velocity shots in 2022 to surpass the 100 km Karman Line which is the edge of space. This Green Launch took place on the morning of Dec 21, 2021 at the Yuma Proving Grounds north of Yuma, Arizona. Here is the launch video.

Green Launch was founded in 2016 by a team of engineers, technicians and physicists. The Green Launch technology spring-boards off record setting hydrogen launcher work at Lawrence Livermore National Laboratory.

The team is betting on the high performance of light gas mixtures as a propellant to deliver goods at velocities above Mach 5 and as high as Mach 20.

“The trick is using a light gas like hydrogen, which has a very low molecular weight,” said CTO Dr. John Hunter. “You can get very high velocities that aren’t possible with railguns or other systems. This has zero carbon emission and will allow us to revolutionize access to space and open the solar system to manned exploration.”

The first practical use for this launch methodology will be atmospheric sampling of the mesosphere to provide crucial data to climatologists. Other potential customers include hypersonic vehicle testing and delivery of satellites and supplies to orbit.

“Your satellites and supplies can be in orbit in 10 minutes,” said Eric Robinson. “We can be launching every 60 to 90 minutes. This will enable us to be the Next Day Air delivery to space.”

“We much appreciate the positive attitude at Yuma Proving Ground and their keeping costs under control. If we went elsewhere, we could never finish the sequence and the world would be denied this very promising launch technology.”

All inquiries are welcome. For more information and videos see the website. www.greenlaunch.space The contact below has more information on this revolutionary Green Launch project.

Media Contact

Eric Robinson (eric.robinson@greenlaunch.space)

Tel: +1.408.422.1096

December 2021

On Dec 21, 2021 a launch tube with a special light gas mixture fired a steel and tungsten projectile towards space at very high speed. It was a quantum leap for space access and exploration. Shot 28 with the Green Launcher was the first vertical shot towards space using a proprietary light gas mix and a 54 foot long, launch tube. Total weight was 28 lbs and the speed exceeded Mach 3. Radar did not capture the projectile but the estimated altitude is 30 km. Its success paves the way for higher velocity shots in 2022 to surpass the 100 km Karman Line. The Karman Line signifies the edge of space. The first Green Launcher is located in the KOFA test range at the Yuma Proving Ground in Arizona. Green Launch was founded in 2016 by a team of engineers, technicians and one physicist. Spring-boarding off of hydrogen launcher work at Lawrence Livermore National Laboratory the team is betting on the high performance of light gas mixtures as a propellant to deliver goods at velocities above Mach 5.

Space access and satellite delivery has been a bewitching topic ever since Newton’s orbital artillery drawings and Jules Verne’s book “From the Earth to the Moon”. With SpaceX now able to supply large cargos of satellites and propellant to orbit, there remains one niche that is impractical for rocket technology. That niche is “just in time delivery”. Just as Fed Ex was born of the necessity for quick delivery of priority packages, Green Launch will be the orbital analog. The region of space between the earth and the moon is becoming populated with satellites and eventually space stations and fuel depots. What happens when an astronaut needs a special tool or needs emergency medical supplies? Typical rocket launch manifests are dedicated to large payloads reserved months in advance. Due to nuances of physics, small rockets cannot reach orbit easily. The smallest rockets that can attain orbit have tiny to non-existent payloads. This is simply because the atmospheric drag on a small rocket is much larger proportionally, than for a large rocket. The Green Launch advantage minimizes the atmospheric drag effect by supplying the initial velocity from the ground. The Green Launcher first shoots the vehicle through the atmosphere at high speed. The vehicle then turns on a rocket engine which supplies the remaining velocity to attain orbit. Voila! The beauty of light gas launchers is that their speeds are far greater than either rail guns or conventional guns. The faster the ballistic launcher, the smaller the rocket and the bigger the payload. Green launch is the fastest.

December 21 was the shortest day of the year. Coyotes were howling auspiciously near the icehouse where the team assembled to get drinking water and notify range safety. Then the 30 minute drive on Pole Line Road. The Green Launch team arrived at Tower 31 Bravo in the KOFA test range at 7:15 am, just prior to sunrise. Simultaneously a meteorological balloon with telemetry was released to measure winds aloft and insure the projectile fired towards space would not drift off the test range during the three minute flight. The next order of business was to elevate the launch tube to 79 degrees and also check the launch Azimuth. Head mechanic Ray Tinker started the generator and hydraulic pump and elevated the launch system, checking the elevation every minute with a small digital gauge. An elevation of 79 degrees was attained after 8 minutes. Two YPG team members verified elevation using an inclinometer which read out in minutes. Both numbers matched, so next the surveyor on a hill directly behind the gun measured the Azimuth. It read out 71 degrees and change. This was well within the Surface Danger Zone as specified by ballistic experts at YPG and ARL. Check. Next Dr. John Hunter and Eric Robinson climbed to the roof of the vertical mount and attached the cable tensioners and tightened the turnbuckles to 500 lbs, which reduced the muzzle droop to near zero.

YPG and Green Launch teams next assembled behind the 4 bomb proof shelters and blast shield 150 ft from the launcher, where a muster was called and a safety talk given by the YPG Test Officer. At that point Hunter began the checklist starting with a firing unit continuity check confirmed by YPG’s Robert Pontizo. The cameras and data recorders were activated by Rob Fryer while Tinker set the gas regulators and opened the manual valves. Both teams then retired to the bombproofs. Four Green Launch personnel attended the gas control panel and diagnostics inside the Conex structure, behind the blast shield. All personnel were accounted for and surveillance cameras showed all clear, so the gas fill began. Robinson operated the controller and started the first gas fill to the target pressure. Within minutes Hunter confirmed the target pressure had been reached so a 4 minute leak test was held. No leak. The second gas fill commenced and the final target pressure was shortly reached. A brief leak test was held and then the Green launch Team left the Conex and entered the bombproofs. Hearing protectors were donned and the YPG test officer instructed Pontizo to perform a 10 second countdown and then fire.

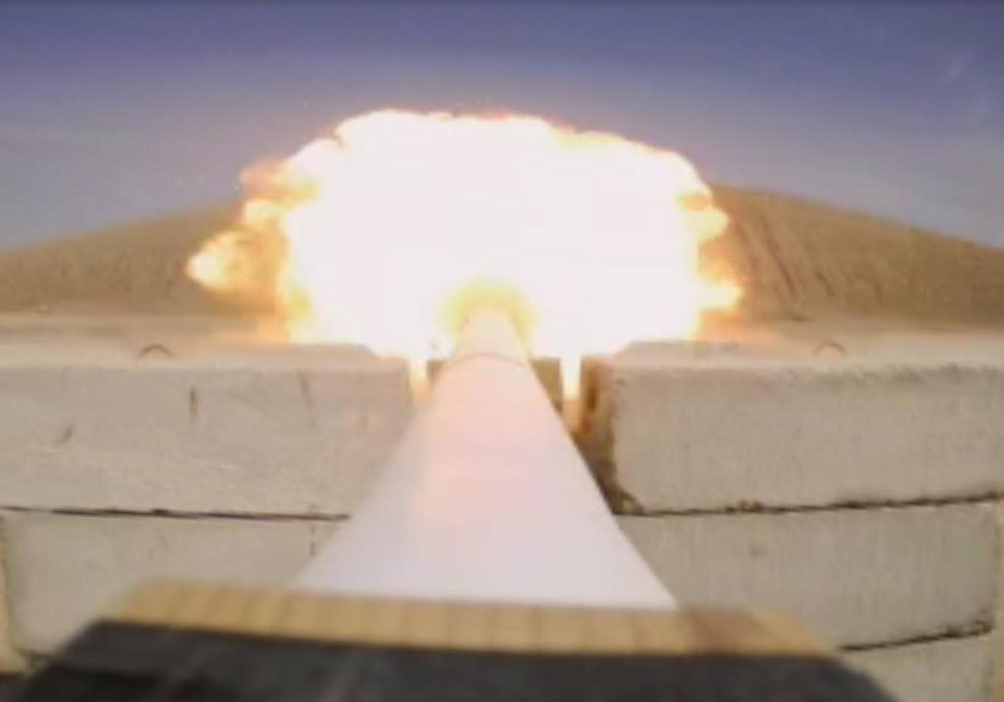

A concussive blast occurred and seconds later the high speed camera crew showed the first video of the projectile leaving the muzzle. All stayed inside the bombproofs for five minutes so that sabot parts would have time to rain down safely. Hunter and Tinker then walked to the launcher and checked the surroundings before an all clear was called.

Afterward, the team headed west for home on Pole Line Road. Near the 20 km marker there is a watering hole for men and equipment. Three wild horses warily stood at attention as the vehicles passed, then resumed their drinking.

A series of shots are planned for early 2022. The ultimate goal is to reach the Karman line as a Proof of Concept. Our combustion light gas technology is tailored to avoid overpressures and a patent is pending. The launch vehicle and sabot will evolve and be improved on. Our technology has left the drawing board and is now being field tested. One near term customer in 2022 is the NSF for atmospheric sampling of the mesosphere. Other potential customers include hypersonic vehicle tests and ultimately satellite and supply delivery to orbit.

Investors are welcome and we are also talking with aerospace companies having complementary technologies.

Feel free to contact us if you or your company would like to hear more about the revolutionary Green Launch project.

Dr. John Hunter, CTO/ Director of Development and Operations

(619) 933-6678

john.hunter@greenlaunch.space

Eric Robinson, Business Development Director

(408) 422-1096

eric.robinson@greenlaunch.space

July 2021 #2

Unlike most military installations, U.S. Army Yuma Proving Ground’s (YPG) primary purpose is not to train troops for combat, but to test the equipment they use to ensure it works as it should.

With a unique mission, YPG’s funding model is also unique. Perhaps 30% of YPG’s funding comes from an allocation from the Department of the Army to cover overhead expenses.

“We have a different model than basically the rest of the Army where we depend on reimbursable work,” said Jeff Rogers, Air Combat Director. “When we’re given our budget, we’re not funded at 100%, so we have to get customers to supplement us.”

Most of this reimbursable work comes from other customers within the Department of Defense, but some comes from private industry customers. In recent years, companies from General Atomics to Facebook have conducted testing at the proving ground with the support of YPG personnel. These customers pay all costs associated with their respective testing.

“It keeps our skills sharp and current, because they can work with the customers and see the newest technologies coming down the pipeline,” said Rogers. “It’s good for the Army because a lot of the systems the Army uses are spawned out of private industry. It’s not that the Army has a big workforce that goes out and creates a whole bunch of new stuff: a lot of what is later used is adapted or adopted from private industry technologies to meet the Army’s needs.”

YPG is a Major Range Test and Facility Base (MRTFB), and The National Defense Authorization Act of 2003 makes facilities with this designation available to other users who have a valid need for them.

“Whenever they decide to execute a test at Yuma, my office takes care of all of the initial contracting and monitoring the contracts,” said Omar Silva, Range Operations and Training Division Chief. “We do that not only for Yuma Test Center, but also for Cold Regions Test Center and Tropic Regions Test Center: we standardize the contracting process across the YPG enterprise.”

Though YPG supports private industry testing, it never competes with private industry.

“There’s law that requires that requires MRTFBs in general across the Department of Defense to not compete with private industry facilities,” said Silva. “Every time a private industry customer wants to come out and test, we need to make sure we aren’t competing with private industry.”

YPG does this by providing a public-facing list of capabilities located here, and attempting to send potential customers to private industry facilities that provide the same services or capabilities prior to agreeing to conduct a test.

“A lot of the time, private industry customers come to us because of our restricted airspace,” said Silva. “You see a lot of private industry aviation testing done here because of the extensive restricted airspace we have that private facilities can’t provide.”

Most of the airspace over the United States is unrestricted. To fly their craft in these conditions, unmanned aircraft developers must acquire a certificate of authorization (COA) from the Federal Aviation Administration (FAA). This is a lengthy and exhaustive process that can take months and is specific not only to the aircraft, but the specific configuration of the aircraft. Thus, if developers want to modify their aircraft in response to their testing, they must get a new COA after every change.

Achieving these stringent conditions is unrealistic for an untested unmanned aerial systems (UAS) in the early stages of development. Additionally, an important part of the developmental process is testing worst-case scenarios. It is unlikely that the FAA would allow such testing in the national airspace. YPG’s 2,000 square miles of restricted airspace, on the other hand, is above miles and miles of land far from any populated area.

There are other benefits to private industry customers conducting aviation testing as well. YPG’s unsurpassed capabilities allow for extensive testing without having to compete for runway and airspace with manned fighter jets as at other installations. Another critical bonus of testing at YPG is the presence of a wealth of other infrastructure meant for other sectors of YPG’s broad test mission that can be leveraged to support UAS evaluations.

YPG is home to things like technical and tactical targets, as well as generator and combined maintenance shops, all of which are useful for UAS testing. YPG’s spectrum management office can also ensures they have the frequencies they need for their specialized testing: YPG has nearly 600 permanent radio frequencies assigned to it, and uses more than 1,000 temporary ones in a given month.

“If we can squeeze them in, it’s great for them and great for us: we get to keep our folks employed and reap the benefit of getting that workload without impacting military test and maximize the air space and range time that we have,” said Silva. “Going to a training base or some other DoD installation can be hard to get into because of training and deployment schedules. As for us, we are an MRTFB and can work them into the schedule.”

Though aviation testing constitutes the bulk of YPG’s private industry work, there are also examples on the ground combat side of the house. The world record for the highest altitude artillery shot was set at YPG in 1966. The test fire more than 50 years ago proved the concept of ballistic suborbital space access, and the idea of using artillery as a low-cost alternative to rockets to launch payloads into Earth orbit lives on. In recent years, a private industry customer called Green Launch has conducted testing here to launch a projectile into space with an innovative hydrogen and oxygen gas propellant whose only byproduct is water vapor.

“YPG is very helpful at keeping our costs under control so we can continue our testing,” said Eric Robinson, Green Launch Business Development Director. “If we went somewhere else, we could never finish the sequence and the world would be denied this technology that is really very promising.”

All three of YPG’s subordinate test center have done testing for private industry customers, and reap the benefits in ways both similar and unique. For example, since its construction in 2004, multiple private industry customers have used the Cold Regions Test Center (CRTC) Mobility Test Complex for their testing.

Hosting commercial testing means the test center’s mobile snow-making machines and other specialized track grooming equipment not found elsewhere in the Department of Defense keeps moving, which saves maintenance costs in the long run. Further, continuous use means the skill the test center’s equipment operators have gained operating the esoteric machines doesn’t degrade: for instance, in unskilled hands a mobile track dryer could ruin the track’s asphalt while melting snow and ice.

“When we have low military workload, being able to do commercial testing allows us to maintain equipment capabilities and the expertise needed for doing those things,” said Jeff Lipscomb, CRTC’s Technical Director. “That way, whenever a military test comes, we’re not scrambling to figure out how to support it. To me, the biggest benefit of the commercial automotive workload is that it keeps us on the cutting edge of automotive testing.”

July 2021

Horizontal Test Firing at Yuma Proving Ground

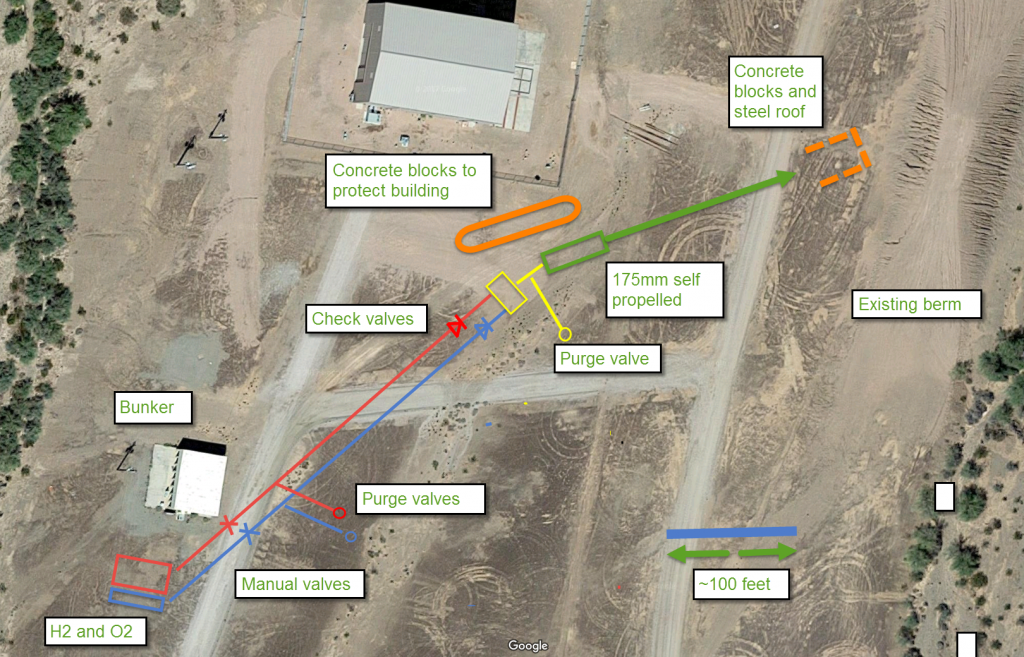

The Green Launch Team completed another series of successful shots at Yuma Proving Ground (YPG) on July 14 and 15. Braving the summer heat were John Hunter, Eric Robinson, Rob Fryer, and Ray Tinker. Each shot involved different parameters of gas charge pressures, release peak pressures, resulting velocities, and for the first time with a “pointy” projectile vehicle capable of containing a payload. We confirmed that the sabot and fins on the projectile were sufficiently rugged to withstand kinetic launch. The “flight mass” total of burst disc, sabot, and projectile was accelerated to a peak velocity of approximately 1.57 km/sec. High-speed camera footage is posted to the website on the “VIDEO” tab.

The next series of test shots at YPG are planned for September and will be vertical up to an expected altitude of 50 km.

Green Launch is starting discussions with a major US space/defense contractor to determine if we can support some of their launch requirements.

March 2021

Despite the gap in these monthly updates, Green Launch has not been idle.

- In 2020, the launch tube was relocated within Yuma Proving Ground. The new location allows for both horizontal and vertical shots.

- New design incorporated for pressure containment within the launch tube.

- Horizontal shot sequence completed with the new design at the new location.

Anticipated launches in summer 2021

- New Payload package designed to contain instrumentation

- Firing sequences both horizontal and vertical

November 2020

Green Launch has achieved a major milestone with a horizontal shot at our new location at Yuma Proving Ground. The new mount for the tube allows adjustable elevation from zero up to 90 degrees.

The recorded shot velocity on November 18, 2020 was 2.03 km / sec.

While we are making changes to the website, I would like to modify the pages for HOME and OUR MISSION. When I open these pages on my computer, the first image fills nearly the entire screen and casual viewers my not bother to scroll down to the other material. Therefore, please edit these images down to a more narrow band so that more of the following stuff is visible.

August 2019

Horizontal Test Firing at Yuma Proving Ground

The Green Launch Team completed another series of successful shots at Yuma Proving Ground (YPG) during June and July. Each shot involved different parameters of gas charge pressures, release peak pressures, vehicle weight, and resulting velocities. Peak velocity achieved was approximately 1.6 km/sec (Mach 4.7). This photo shows a plastic slug impact with a 5-gallon water bottle.

Presentation at New Space Conference

Green Launch was accepted to make a presentation at this event in Seattle, WA held on July 16 to 18. We were pleased to be included among a select “new space” group of developing revolutionary space launch concepts.

Presentation at Icarus Interstellar Conference

Green Launch is on the agenda to make a presentation at this event in San Diego, CA held on September 13 to 15.

Velocity Improvements

We are considering various options to improve the performance of the launch tube: boring out the chamber to increase gas volume, tube extension which would also increase velocity, use of other tubes with larger diameters.

June 2021

YUMA PROVING GROUND, Ariz.– From Jules Verne until the dawn of the rocket age, scientific thinkers and dreamers assumed that massive artillery fire was the logical means of accelerating payloads into the heavens.

Original article source credited to www.army.mil

Even in the 1960s, as NASA perfected the massive, multi-stage Saturn V rockets that propelled humanity to the moon–and U.S. Army Yuma Proving Ground (YPG) tested the Mobility Test Article, precursor to the lunar rover–the Army was conducting the High Altitude Research Project (HARP), which intended to utilize artillery fire as a lower cost alternative to launching scientific payloads into Earth orbit. The world record for the highest altitude shot–which reached past the Karman Line into space– was set at the proving ground in 1966. It proved the concept of ballistic suborbital space access, but funding for the program was cancelled the following year.

The original HARP cannon and several smaller gun tubes associated with those long-ago tests remain at YPG and are still viable for firing with a relatively small amount of refurbishment. Currently, a private industry customer called Green Launch is at YPG conducting early of launching a space projectile with some of this equipment, combined with an innovative new technology.

Using a hydrogen and oxygen gas propellant, the company feels that as humanity expands its presence in the Solar System in the coming decades, impulse-launched deliveries of supplies and materials will be critically important, particularly given the vast sums of money required for humanity’s first forays to places like Mars.

“It takes a million pounds of fuel per person to get to Mars and back,” said Eric Robinson, strategic outreach manager. “Multiplied by $5,000 per pound, that’s $5 billion just for fuel. Our system would be more like $200 per pound. Hydrogen and oxygen are cheap.”

Another advantage of artillery-fired delivery of objects would be the speed and frequency of fire: they could ascend faster and be repeated with less work than multi-stage rockets.

“Your items could be in orbit in five minutes,” said Robinson. “We could be launching every 60 to 90 minutes. This will enable us to be the FedEx of space.”

It would also be significantly more environmentally-friendly than burning rocket fuel.

“At the very end of a shot, a little bit of a steam cloud comes out, because hydrogen and oxygen make water,” said Robinson. “The eventual design may use a solar-heated steam piston and hydrogen that is 95% recaptured after each launch.”

The early phase of testing in progress now consists of horizontally firing a high density plastic slug through a velocity trap into a specially-constructed catch box in front of a thick earthen berm.

“The set-up is very similar to that of many other firing tests, but this is truly a developmental test,” said Chris Tennant, test officer. “A lot of tests at YPG are lot acceptance or stockpile reliability tests, or engineering tests where most of the components are known and one portion of a system is being changed.”

To prepare a launch, the testers insert a burst diaphragm, followed by an o ring behind the plastic slug. Finally, an ignition assembly with squibs the testers have dubbed the ‘Christmas tree’ is loaded. The testers have added feed tubes that push hydrogen and oxygen gas into the gun. Once enough gas pressure is built up behind the diaphragm, the testers ignite it from a bombproof control room panel and the projectile fires.

“We really haven’t modified the gun significantly, except for the breach section,” said Dr. John Hunter, chief technical officer. “It’s made for a solid propellant, which is why the available breach volume is fairly small. We prefer a much bigger breach, so when we do the vertical shots we’ll probably end up pushing the projectile about a third of the way in the barrel and use a specialized release mechanism that gives about three times the volume.”

At this stage, testers are primarily interested in measuring projectile velocity and ensuring the burst diagram performs in a controlled manner. So far, with horizontal fires, the testers have already achieved velocities similar to that of the HARP vertical shot that set the world record in 1966. They want to achieve even faster velocities before converting to vertical test fires of their system.

“The trick is using a light gas like hydrogen, which has a very low molecular weight,” said Hunter. “You can get very high velocities that aren’t possible with powder. This exceptional propellant will allow us to revolutionize access to space and open the solar system to exploration and resources.”

“Hydrogen is super-fast, and the ignition and energy from making water is a very energetic exothermic reaction,” added Robinson.

Green Launch is a start-up company that seeks rigorous cost control to ensure the long-term perpetuation of their ambitious program. Hunter, highly regarded in the projectile research community for many decades, was only marginally aware of YPG and its capabilities until a chance meeting with proving ground personnel.

“I went to a conference in New Mexico five or 10 years ago and ran into some high speed photographers who told me the best test range is YPG,” said Hunter.

“YPG is very helpful at keeping our costs under control so we can continue our testing,” added Robinson. “If we went somewhere else, we could never finish the sequence and the world would be denied this very promising technology.”

For their part, YPG personnel are excited about their role in supporting what could turn out to be a project of monumental importance.

“If they can get the muzzle velocity they want, they intend to eventually shoot vertically,” said Tennant. “I’m hoping we can make it happen here and break the world altitude record that was set at YPG back in 1966.”

May 2018

ACCOMPLISHMENTS

Horizontal Test Firing at Yuma Proving Ground

The Green Launch team completed another series of four successful shots at Yuma Proving Ground (YPG) during the week of April 23. Two shots per day were achieved using YPG personnel and our team. Gas manifold and controls are working well. Shots 14, 15 and 16 in April saw speeds up to 2 km/s. Next horizontal test series in June will assure performance of vertical test series to Karman Line. The photo shows the muzzle blast with hydrogen igniting. Plastic vehicle slug impacts the dirt berm.

WORK IN PROGRESS

Presentation at International Space Development Conference

Green Launch has been accepted to make a presentation at this annual event sponsored by the National Space Society. This year it will be held on May 24 – 27 at the Sheraton Gateway Hotel, Los Angeles. We hope to have a chance to meet you at the Conference.

March 2018

ACCOMPLISHMENTS

Horizontal Test Firing at Yuma Proving Ground

Green Launch has been busy with a series of 12 successful shots which began in December and continued through the first part of March. Each shot involved different parameters of gas charge pressures, release peak pressures, vehicle weight, and resulting velocities. This collection of data demonstrates the principal of light gas propulsion to achieve high velocities in the field. We plan at least one more series of test shots in April. The following photos give an idea of the setup.

- Gun Connection to Gas Supply

- Gun setup at YPG

- Gun Mounted with Support

- Gun Mounting on Carriage

Green Launch Trademark Approved

The US Patent Office has finally approved our logo design and associated description of services to be offered by Green Launch.

WORK IN PROGRESS

Presentation at International Space Development Conference

Green Launch has been accepted to make a presentation at this annual event sponsored by the National Space Society. This year it will be held on May 24 – 27 at the Sheraton Gateway Hotel, Los Angeles. We hope to have a chance to meet you at the Conference.

September 2017

ACCOMPLISHMENTS

Presentation at Mars Society Annual Convention

The Green Launch (GL) core team (John Hunter, Eric Robinson, Rob Fryer, and Don Whitney all attended this held at University of California, Irvine on September We presented the overview concept and received many questions from the interested group of space enthusiasts. The featured guest speaker at the convention was Anousa Ansaria who described her journey to becoming the first civilian to reach the International Space Station.

Preliminary Patent Applications Submitted

There are several aspects of the Green Launch system which we belief are novel and patentable. Therefore, John Hunter has written these up and submitted them to the US Patent Office for approval.

WORK IN PROGRESS

Pneumatic Components Assembly

This work is under way in San Diego. A convenient location has been confirmed for assembly and testing of the pneumatic manifolds to deliver the various gases to the launch tube. Each manifold will consist of valves gauges and connects mounted on a panel to allow for easy transportability and assembly.

June 2017

ACCOMPLISHMENTS

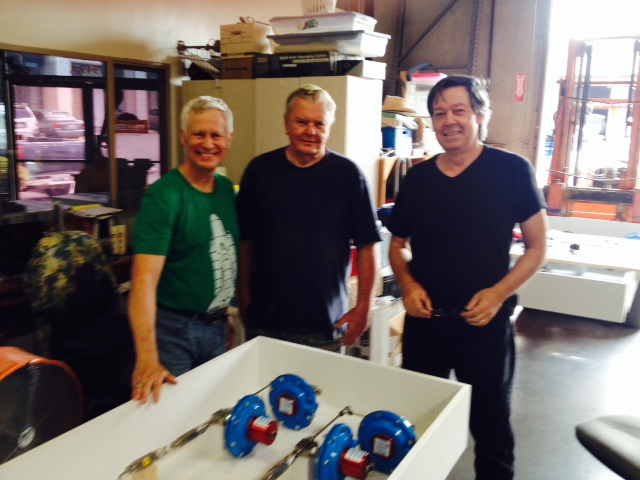

Pneumatic Components Received

Phil Sluter of TriAxial Design and John Hunter refined and optimized the tubing and fittings to control the gas loading of the gun and safe firing. Firm order was placed on June 2 for the major components. Essentially all of the parts have now been received and assembly started on July 6. Photo shows Don Whitney, Ray Tinker, and John Hunter with one of the four main manifold panels.

Preliminary Patent Applications Submitted

There are several aspects of the Green Launch system which we belief are novel and patentable. Therefore, John Hunter has written these up and submitted them to the US Patent Office for approval.

WORK IN PROGRESS

Green Launch on TV

Due to studio logistical problems, John Hunter and Eric Robinson did not get to complete the taping session for a national television show. However, we hope to have another opportunity this coming Fall to appear on the show and thereby publicize Green Launch and increase awareness of our activities.

Pneumatic Components Assembly

This work is under way in San Diego. A convenient location has been confirmed for assembly and testing of the pneumatic manifolds to deliver the various gases to the launch tube. Each manifold will consist of valves gauges and connections mounted on a panel to allow for easy transportability and assembly. We also plan a subscale testing of the gun components.

May 2017

ACCOMPLISHMENTS

Yuma Test Preparations

John Hunter and Don Whitney made another 3-day trip to YPG starting May 1 to coordinate several aspects of preparation for a series of horizontal test shots this summer:

• Meeting with YPG staff to discuss our test plans and schedule

• Tour and measurements of EM Building for optimum location of gun, target area, gas cylinders, and connection to control bunker

• Review of draft SOP /checklists for gun operation

• Refinements of pneumatic components and fail-safe operations

Green Launch Logo and Sales Mark

We have submitted the online application to register the logo and stylized format of Green Launch with the US Patent and Trademark Office.

Pneumatic Components Order Finalization

John Hunter has refined and optimized the tubing and fittings to control the gas loading of the gun and safe firing. Firm order was placed on June 2 for the major components.

WORK IN PROGRESS

Green Launch on TV

John Hunter and Eric Robinson have been tentatively invited to appear on a national television show. This will be a great opportunity to publicize Green Launch and increase awareness of our activities.

Preliminary Patent Application in Progress

There are several aspects of the Green Launch system which we belief are novel and patentable. Therefore, we are in the process of preparing an application.

April 2017

ACCOMPLISHMENTS

Kickstarter Campaign

We believe that the elements of the campaign materials and video make a good case for the Green Launch development and test plan. Unfortunately, it looks like the online pledges will fall short of the goal of $95,000. However, our horizontal test development will move forward with the money we have on hand (see below).

Yuma Proving Ground (YPG) Test Contract

The U.S. Army has incorporated our Green Launch plan of test activities into a formal contract. Don Whitney signed the contract for Green Launch and the YPG Test Directorate has also signed. Now we can proceed with using YPG equipment and manpower as required.

Yuma Test Preparation

John Hunter made another trip to YPG starting April 17 to coordinate several preparation aspects:

• Gun tube (7” x 55’) has been moved from the “bone yard” to an inspection / work area

• Gun tube interior cleaned and visually inspected for imperfections (none found)

• Breech block separated and moved to San Diego for modifications for gas connections

Interest from Supporters and Investors

A testament to the potential of the Green Launch concept is continuing contacts and inquiries we receive through our website.

• Technical questions and suggestions about Green Launch

• Offers to invest in Green Launch (none accepted at this point)

• Inquiry from a major defense contract about horizontal research firing

Green Launch on The Space Show

John Hunter was interviewed by Dr. Livingston on the radio / online show and took questions from the public about Green Launch.

WORK IN PROGRESS

Horizontal Test Preparation

John Hunter is continuing to plan for a series of 15 test shots this summer at YPG

• Design of test plan with gradually increasing chamber pressures

• Sourcing light gas mixtures, storage tanking, and pricing from suppliers

• Sourcing gas piping, fittings, and controllers from suppliers

• Layout of test components and target area at the YPG range

• Test operating procedures and safety protocols

March 2017

ACCOMPLISHMENTS

Kickstarter Campaign

The elements of the campaign materials have been completed and been approved by the Kickstarter organization. These include a text description of Green Launch, a video, and rewards for different levels of contributions. The Green Launch team has commitments of $120,000 from team members, family, and friends towards Phase 1 of the program. We estimate that this is slightly more than half of the expense required to achieve the Phase 1 goal of a launch to the Karman Line of space. Therefore, we have set a Kickstarter campaign goal of $95,000. The campaign should start officially in mid-March. Please visit the website and make a contribution.

The elements of the campaign materials have been completed and been approved by the Kickstarter organization. These include a text description of Green Launch, a video, and rewards for different levels of contributions. The Green Launch team has commitments of $120,000 from team members, family, and friends towards Phase 1 of the program. We estimate that this is slightly more than half of the expense required to achieve the Phase 1 goal of a launch to the Karman Line of space. Therefore, we have set a Kickstarter campaign goal of $95,000. The campaign should start officially in mid-March. Please visit the website and make a contribution.

Yuma Proving Ground (YPG) Testing Contract

The U.S. Army has incorporated our Green Launch plan of activities for testing into a formal contract. Don Whitney signed the contract for Green Launch and returned it to the YPG Test Directorate for their signature. Expect final signatures in April.

WORK IN PROGRESS

YPG Testing Contract

Green Launch delivered our plan of activities for testing to the YPG Test Directorate. The contract for YPG services and range use is now in review with government contract staff. Expect final signatures early 2017.

Green Launch at Mars Society

John Hunter has been invited to give a plenary talk at the Mars Society annual convention at UC Irvine CA, September 7-10, 2017. Schedule permitting, we will try to be there.

WORK IN PROGRESS

Horizontal Test Preparation

John Hunter and Phil Sluder made another trip to YPG on March 30. The purpose was to make further detailed measurements of the 175 mm tube so that detailed drawings can be made. They also met with YPG personnel to discuss horizontal test locations on the range and plans for NDT testing of the tube.

February 2017

ACCOMPLISHMENTS

Kickstarter Campaign

The elements of the campaign materials have been completed and been approved by the Kickstarter organization. These include a text description of Green Launch, a video, and rewards for different levels of contributions. The Green Launch team has commitments of $120,000 from team members, family, and friends towards Phase 1 of the program. We estimate that this is slightly more than half of the expense required to achieve the Phase 1 goal of a launch to the Karman Line of space. Therefore, we have set a Kickstarter campaign goal of $95,000. The campaign should start officially in mid-March. Please visit the website and make a contribution.

WORK IN PROGRESS

YPG Testing Contract

Green Launch delivered our plan of activities for testing to the YPG Test Directorate. The contract for YPG services and range use is now in review with government contract staff. Expect final signatures early 2017.

Green Launch at Mars Society

John Hunter has been invited to give a plenary talk at the Mars Society annual convention at UC Irvine CA, September 7-10, 2017. Schedule permitting, we will try to be there.

January 2017

ACCOMPLISHMENTS

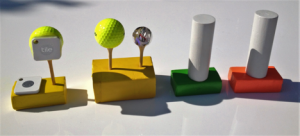

Small Payload Design Demonstration

John Hunter has been experimenting with small off-the-shelf commercial components which can be assembled into our expected early payload volume (white cylinders) approximately 1 ¼ inch diameter by 4 inches long. These components can be programmed from a laptop computer to perform various functions. The blue model is a notional design for the vehicle and the white sabot structure will enclose the vehicle and provide support within the walls of the launch tube. The yellow golf balls provide a visual demonstration that modern electronics can take 30,000 Gs with minor modifications.

Don Whitney at Lions Club of Downtown Oklahoma City

Don presented the Green Launch PowerPoint at the January 24 meeting of this illustrious 100 year-old club of the city. Enthusiastic club members and high school seniors asked many questions.

Eric Robinson collects Green Launch Supporters and Advisors

Eric is in the process of contacting recognized space experts to obtain their endorsements of the Green Launch concept of efficiently delivering small payloads to orbit. Names will be posted to the website as collected.

Green Launch, LLC

This business name has been registered in the state of Oklahoma. Accounts with this name have been created at a bank, PayPal, and a credit card company to pay expenses and to receive donations.

WORK IN PROGRESS

YPG Testing Contract

Green Launch delivered our plan of activities for testing to the YPG Test Directorate. The contract for YPG services and range use is now in review with government contract staff. Expect final signatures early 2017.

Kickstarter Campaign

Additional funding will be required beyond the amounts pledged by team members, family, and friends. We plan to use social media “crowd funding” to generate the rest. The campaign description, rewards, and other details are now in development. Expected start date early 2017.

Small Payload Design Demonstration

Rob Fryer and John Hunter have been experimenting with small off-the-shelf commercial components which can be assembled into our expected early payload volume of a cylinder approximately 1 ¼ inch diameter by 4 inches long. These components can be programed from a laptop computer to perform various functions.

December 2016

ACCOMPLISHMENTS

Yuma Proving Ground (YPG) Facility Photos

Green Launch Team visited YPG on October 18 through 20, 2016. We took many photos which have now been released by the Public Information Office. These facilities, equipment, and services will be invaluable for our series of test launches. Photos top to bottom:

- Carriage to support and transport the 7-inch x 55-foot tube

- EM building for storage and support of horizontal testing

- Dirt berm for horizontal testing impact

- Metal structure to elevate and support tube for vertical firing

Dr. John Hunter at San Diego State University (SDSU)

John did the Green Launch PowerPoint presentation at a December 7 meeting of the American Institute of Aeronautics and Astronautics (AIAA) student chapter.

Facebook Page

An early version is now on line. Please check it out periodically for updates and new material. Link:

https://www.facebook.com/ImpulseLaunch/

Website Page

ZenThree has developed a customized webpage for Green Launch. Please check it out periodically for updates and new material. Link: http://greenlaunch.space

WORK IN PROGRESS

YPG Testing Contract

Green Launch delivered our plan of activities for testing to the YPG Test Directorate. The contract for YPG services and range use is now in review with government contract staff. Expect final signatures early 2017.

Kickstarter Campaign

Additional funding will be required beyond the amounts pledged by team members, family, and friends. We plan to use social media “crowd funding” to generate the rest. The campaign description, rewards, and other details are now in development. Expected start date early 2017.

Small Payload Design Demonstration

Rob Fryer and John Hunter have been experimenting with small off-the-shelf commercial components which can be assembled into our expected early payload volume of a cylinder approximately 1 ¼ inch diameter by 4 inches long. These components can be programed from a laptop computer to perform various functions.

November 2016

ACCOMPLISHMENTS

Yuma Proving Ground (YPG) Site Visit

Yuma Proving Ground (YPG) Site Visit

Four Green Launch team members (photo L-R: John Hunter, Don Whitney, Steve Kane, Rob Fryer) visited YPG on October 18 through 20, 2016. Major activities included discussions with YPG staff on support available, tour and selection of optimum range sites for horizontal and vertical firing, video inspection of tube interior (looks good!), and painting exterior of tube white.

Dr. John Hunter on the radio The Space Show

John gave a detailed overview of Green Launch plans to demonstrate the practical application of economical impulse launch to space. The format was a live interview with Dr. David Livingston and aired on October 9, 2016.

http://www.thespaceshow.com/show/09-oct-2016/broadcast-2791-dr.-john-hunter

Facebook Page

An early version is now on line. Please check it out periodically for updates and new material. Link:

https://www.facebook.com/ImpulseLaunch/

PowerPoint

A Power Point overview of the Green Launch vision has been developed to be posted on the webpage and other media. The 27-page briefing includes the heritage of similar programs, performance expectations, and the business case for impulse launch.

WORK IN PROGRESS

YPG Testing Contract

YPG Testing Contract

Green Launch prepared and delivered our plan of activities for testing to the YPG Test Directorate. The contract for YPG services and range use is now in review with government contract staff. Expect final signatures in December 2016.

Website

A contract has been signed with ZENTHREE to develop a website for Green Launch. Please check it out periodically for updates and new material. Expect activation by end of November or early December 2016. Link: http://greenlaunch.space

Kickstarter Campaign

Additional funding will be required beyond the amounts pledged by team members, family and friends. We plan to use social media funding to generate the rest. The campaign description, rewards, and other details are now in development. Expect start date in January 2017.

Small Payload Design Demonstration

Rob Fryer has been experimenting with small off-the-shelf commercial components which can be assembled into our expected early payload volume of a cylinder approximately 1 ¼ inch diameter by 4 inches long. These components can be programed from a laptop computer to perform various functions.